VERTICAL TWO RAM BALER

Heavy Duty Multi-Material Vertical Two Ram Baler With Pressing Force Up To 200tons (440,000lbs)Makabale heavy duty vertical two ram baler is an extremely rugged and powerful downstroke baler which is engineered with highest steel quality combined with large compressing force for superior performance in baling recyclables of hard plastic, fluffy material, fibrous products and high rebounding force. This baling press is also a perfect solution for those who are looking to make highest density bales of common soft waste materials to reduce the cost of handling and transportation while maximizing the recycling revenue. Ideal For: Recycling Centers, Natural Fiber Dealers/Exporters, Manufacturing Facilities, Hard Plastic Recyclers, Warehouses, Transfer Stations, Other Industrial/Commercial Sites. |  |

|

|

Features And Benefits Of The Vertical Two Ram Baler:

|

Details And Options

STANDARD AUTO CHAIN BALE EJECTOR

After a bale is tied up, place the ejector chains on the ram retract hooks on the back of the baler. The bale will be automatically ejected out from the chamber when the platen retracts.

OPTIONAL HYDRAULIC-DRIVEN CHAMBER DOOR

The baler chamber door can automatically open or close by pressing a button on electric panel instead of handwheel, which saves labor and increases efficiency.

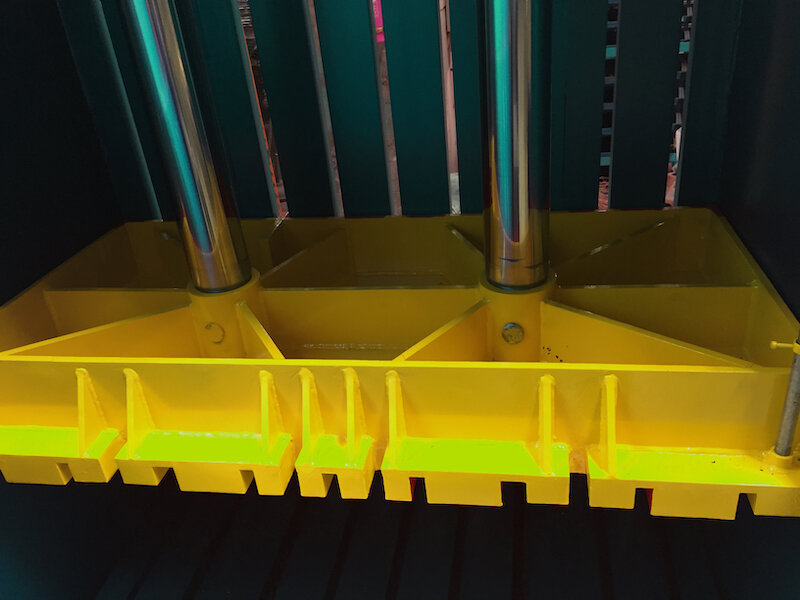

OPTIONAL RETAINING TEETH

Optional retaining teeth on chamber door and rear of the baler can prevent the compressed material from spring back, thus increase the bale density and stability.

CHAMBER DOOR OPEN OPTIONS

The chamber door has 4 open options depending on different baling materials, including front opening, front and back opening, front and one side opening, all 4 doors opening.

The Vertical Two Ram Baler Can Bale:

PET Bottles

Aluminum Cans

Paper Carton

Coconut Fibers/Coir

Cardboard/OCC

Paper

Fur/Animal Hair Fibers

Un-chopped Straw/Hay

Bast Fibers

Leaf Fibers

Rigid Plastics

Extruded Aluminum

The Right Waste Recycling Two Ram Baler For The Job!

Makabale offers 7 standard models of vertical two ram baler for sale. All the baler presses are built for a variety of waste material types and industries. Choose from these models or contact us for a customized baler to meet your unique requirements.

| Baler Model | Bale Size (L x W x H) | Bale Weight (coir) | Feed Opening (L x H) | Press Force (max.) | Bales Per Hour (approx.) |

| VHD80 | 1520mm x 760mm x up to 1000mm (60” x 30” x up to 39”) |

125-270kg (275-595lbs) | 1520mm x 650mm (60” x 26”) |

80tons(176,000lbs) | 3 |

| VHD120-11070S | 1100mm x 700mm x up to 1000mm (43” x 28” x up to 39”) |

70-220kg (154-485lbs) | 1100mm x 500mm (43” x 20”) |

120tons(264,000lbs) | 4 |

| VHD120-15276S | 1520mm x 760mm x up to 1000mm (60” x 30” x up to 39”) |

145-300kg (320-661lbs) | 1520mm x 650mm (60” x 26”) |

120tons(264,000lbs) | 3 |

| VHD150-11070S | 1100mm x 700mm x up to 1100mm (43” x 28” x up to 43”) |

100-260kg (220-573lbs) | 1100mm x 500mm (43” x 20”) |

150tons(330,000lbs) | 4 |

| VHD150-15276S | 1520mm x 760mm x up to 1100mm (60” x 30” x up to 43”) |

190-355kg (418-782lbs) | 1520mm x 650mm (60” x 26”) |

150tons(330,000lbs) | 3 |

| VHD200-11070S | 1100mm x 700mm x up to 1100mm (43” x 28” x up to 43”) |

120-300kg (264-660lbs) | 1100mm x 500mm (43” x 20”) |

200tons(440,000lbs) | 4 |

| VHD200-15276S | 1520mm x 760mm x up to 1100mm (60” x 30” x up to 43”) |

210-400kg (462-880lbs) | 1520mm x 650mm (60” x 26”) |

200tons(440,000lbs) | 3 |

*Specifications & Dimensions are subject to change without prior notice. Bale weights and performance rates are approximate and depending on material type, feed speed, and other variables in baling process.

Vertical Two Ram Baler Frequently Asked Questions

A heavy-duty vertical two ram baler is a type of industrial recycling equipment designed for compressing large volumes of waste materials like cardboard, plastic, and scrap metal into dense, manageable bales. It features two hydraulic cylinders that apply pressure vertically to achieve higher compaction rates.

This baler is predominantly used in industries requiring efficient waste management and recycling processes, including manufacturing facilities, recycling centers, and distribution warehouses. It's particularly effective for handling high volumes of recyclable materials, or tough materials, or fluffy materials.

Vertical two ram balers can process a variety of materials, including cardboard, plastics (PET, HDPE), textiles, metal scraps (aluminum cans, aluminum siding, sheet aluminum, insulated copper wires, bare bright copper, copper tubing, stainless steel), coconut fiber, and more. Their robust design allows them to handle tougher and more voluminous waste compared to single-ram balers.

The primary benefits include:

Increased efficiency: Dual rams provide stronger compression, leading to denser bales.

Space saving: Denser bales mean reduced storage space requirements.

Cost-effective: Reduced volume of waste leads to lower transportation and handling costs.

Environmentally friendly: Facilitates recycling and reduces landfill usage.

A vertical two ram baler uses two rams to exert pressure, which results in higher compression force and denser bales. Two rams usually applies when the hydraulic pressure is high, and the two-ram feature can let the pressure and platen be more even during compressing process. This contrasts with single-ram balers that use only one hydraulic ram, making them more suitable for lighter and less voluminous waste.

Regular maintenance is crucial and includes checking hydraulic oils, inspecting hoses and connections for leaks, ensuring rams are lubricated, and verifying that safety mechanisms are functional. Scheduled downtime for maintenance helps prevent unexpected breakdowns and prolongs the lifespan of the baler machine.

Vertical two ram balers are generally more expensive than less powerful single-ram balers due to their more complex design and higher performance capabilities. However, the increased efficiency and potential savings in waste handling and recycling can justify the initial higher investment for many businesses.

Yes, Makabale offers customization options such as varying bale sizes, pressure, configurations, as well as additional features like hydraulic door closing/open for saving labor, which can be tailored to meet specific operational requirements of different businesses.

Vertical two ram baler is available from Makabale. We offer a few standard models and customization based on users’ needs. Contact us to find out how we can help on your baler needs.

GOT A QUESTION ABOUT THE VERTICAL TWO RAM BALER?

Talk with One of Our Experts in Waste Recycling Solutions

Our skilled professional team is waiting to help you with your unneeded waste materials and propose to you our recycling solutions. We also back up these proposals with our able technical support to make your recycling efforts earn more money by being more efficient.