MINI BALER / MARINE GARBAGE COMPACTOR

The Mini Baler / Marine Garbage Compactor Is A Multi-Material Small Baler Perfect For Small Sized Recycling Or Waste Disposal.Makabale vertical hydraulic mini balers are designed exactly for those who are looking for the easiest-to-handle baler with the very smallest footprint. These mini balers are small-sized, compact recycling machines which are safe and easy to operate. They produce compacted bales which can then be easily handled. The small size makes mini balers the ideal solution for a wide range of businesses and facilities, including supermarkets, retail stores, hotels, schools, hospitals, vessels, offices, restaurants, houses, and small businesses. Mini balers can bale various soft waste materials, including paper, cardboard, cans, plastic wrap, plastic bottles, plastic foils, and textiles. These machines conveniently turn large volume, recyclable waste into small, rectangular, dense bales for easy handling and transporting. This is a way for your business or property to save space, time, and money. The Makabale mini baler has a compressing force of 10-20 tons depending on the model. It produces a bale weighing 20-120 kg (about 40-260 lbs). The machine is small and shorter, so it requires less operation area and ceiling height, and fits into more places, compared to other vertical balers. Ideal For: Supermarkets, Retail Stores, Hotels, Schools, Grocery Stores, Hospitals, Vessels, Offices, Houses, Restaurants |  |

|

|

Features And Benefits Of The Mini Baler / Marine Garbage Compactor:

|

Details And Options

STANDARD AUTO CHAIN BALE EJECTOR

After a bale is tied up, place the ejector chains on the ram retract hooks on the back of the baler. The bale will be automatically ejected out from the baler chamber with the platen retracts.

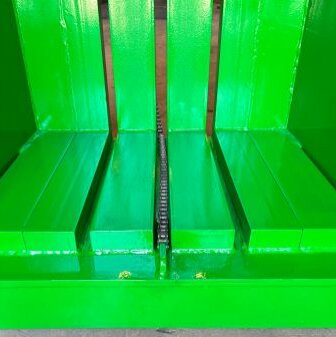

LIQUID DRAINAGE CHANNEL

Optional liquid drainage channel is to drain the liquid out of the baler if you are baling PET bottles or cans which contains liquid. It helps you keep a safe and clean baling area.

SAFETY INTERLOCK SYSTEM

An interlock system is fixed in feeding chamber to ensure safe operation. The platen does not move if doors are open.

HIGH-DENSITY POLYETHYLENE GUIDE ON PLATEN

Replaceable high-density polyethylene guides on platen absorb the side force to the chamber walls to ensure smooth and quiet running.

The Mini Baler / Marine Garbage Compactor Can Bale:

Cardboard/OCC

Paper

Paper Carton

Textiles

Aluminum Cans

PET Bottles

Municipal Waste

Soft Plastics

The Right Waste Baler Compactor For The Job!

Makabale offers 4 standard models of mini baler / marine garbage compactor for sale. All the baler presses are built for a variety of waste material types and industries. Choose from these models or contact us for a customized baler to meet your unique requirements.

| Baler Model | Bale Size (L x W x H) | Bale Weight (OCC) | Feed Opening (L x H) | Press Force (max.) | Bales Per Hour (approx.) |

| VMN10 | 650mm x 400mm x up to 500mm (26” x 16” x up to 20”) |

20-40kg (44-88lbs) |

650mm x 400mm (26” x 16”) |

10tons (22,000lbs) | 7 |

| VMN15 | 650mm x 400mm x up to 500mm (26” x 16” x up to 20”) |

25-50kg (55-110lbs) |

650mm x 400mm (26” x 16”) |

15tons (33,000lbs) | 7 |

| VMN20A | 650mm x 400mm x up to 500mm (26” x 16” x up to 20”) |

30-60kg (66-132lbs) |

650mm x 400mm (26” x 16”) |

20tons (44,000lbs) | 7 |

| VMN20B | 750mm x 500mm x up to 600mm (30” x 20” x up to 24”) |

50-100kg (110-220lbs) |

750mm x 400mm (30” x 16”) |

20tons (44,000lbs) | 7 |

*Specifications & Dimensions are subject to change without prior notice. Bale weights and performance rates are approximate and depending on material type, feed speed, and other variables in baling process.

Mini Baler / Marine Garbage Compactor Frequently Asked Questions

A mini baler is a compact machine designed to compress materials like textiles, cardboard, plastic, beverage cans, or packaging materials into small, manageable bales. It's an ideal choice for small-scale operations.

A mini baler uses hydraulic pressure to compress materials into bales. It's a smaller and more portable version of its larger counterparts but carries out the same essential functions. It operates efficiently to minimize the space occupied by the waste.

There are mainly 4 steps of operation: 1) Feeding material; 2) Compressing; 3) Tie up the bale; 4) Eject out the bale.

A mini baler can be found in:

Supermarkets

Retail environments

Recycling centers

Ships

Other locations where space is at a premium

Space-Saving: Perfect for smaller spaces.

Energy-Efficient: Consumes less power compared to a full-sized baler.

Cost-Effective: Generally more affordable to purchase and maintain.

Versatile: Suitable for different materials.

Choosing a mini baler requires consideration of:

Material Type

Baling Volume

Space Availability

Budget

Considering these factors will ensure that the machinery fits the task at hand.

There will be detailed maintenance guidelines provided by the manufacturer. Such as:

Regular Inspection: Check for wear and tear.

Cleaning: Keep the baler free from debris.

Proper Lubrication: Keep moving parts well-lubricated.

Replacing the hydraulic oil after certain period of operation time.

GOT A QUESTION ABOUT THE SMALL WASTE BALER?

Talk with One of Our Experts in Waste Recycling Solutions

Our skilled professional team is waiting to help you with your unneeded waste materials and propose to you our recycling solutions. We also back up these proposals with our able technical support to make your recycling efforts earn more money by being more efficient.