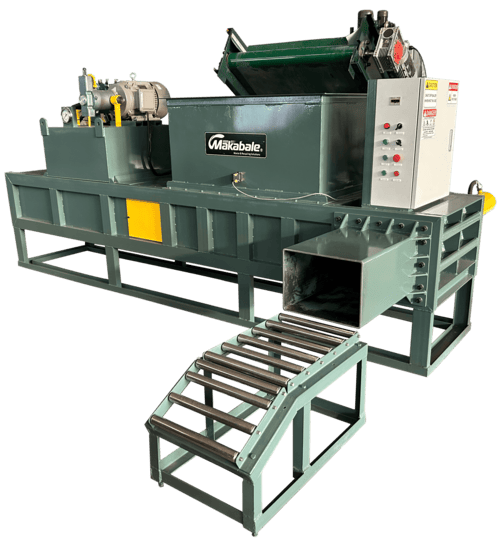

HEAVY DUTY BAGGING BALER / HAYLAGE BALER

The Heavy-duty Bagging Baler / Haylage Baler Is A Combination Of Baling And Bagging For Any Small Materials.Makabale heavy duty horizontal bagging baler is the perfect machine for baling or repacking loose materials in small pieces such as wood shavings, chips, timber mill residue, chopped straw, chopped hay, haylage, flax, sawdust, rice husk, etc. The whole baling and bagging process is completely automatic and is controlled by a programmable controller installed in the control box. With firstly have a plastic bag fitted to the ejection bale chute, the operator just presses one button, this machine will compress the material and eject the dense bale into the pre-fitted plastic bag. This baler has a large built-in hopper where the materials is fed in can be either by manually or automatically with a conveyor. This bagging baler is with higher compress force (ranging from 40 to 80 tons depending on models) and with bigger bale size compared with weighing scale bagging baler. Ideal For: Wiper/Rag Dealers, Textile Recyclers, Animal Bedding Manufacturers, Animal Feed Manufacturers, Fertilizer Manufacturers, Farms and More. |  |

|

|

Features And Benefits Of The Heavy-duty Bagging Baler / Haylage Baler:

|

Details And Options

ONE BUTTON OPERATION

The machine can press, eject, and bag the bale in a continuous step just by pressing one button.

PLC AUTOMATION

PLC automates operation, increases accuracy and ensures safety.

OPTIONAL FEEDING CONVEYOR

Feeding conveyor is optional for automatically loading materials into baler continuously. The sensor on hopper can detect the material level to start or stop the conveyor. This helps you save labor and increase production.

BAG PACK

Bag packed materials are dampproof and cost-saving on transport and storage. Also easy for transport and storage.

HOPPER OPTIONS

An optional upgraded extended hopper is available for storing more material in the hopper.

OPTIONAL DUST PROTECTION

An optional dust protection cover above hopper is available. It can be added if you are baling materials which will generate a lot of dust during the feeding and baling process.

OPTIONAL BLADES

An option of shearing blades on feeding mouth is available to avoid jam when pressing. It can be added if your baling materials are in long pieces.

The Heavy-duty Bagging Baler / haylage Baler Can Bale:

The Right Heavy-duty Bagging Baler / haylage Baler For The Job!

Makabale offers 4 standard models of heavy-duty bagging baler / haylage baler for sale. All the baler presses are built for a variety of waste material types and industries. Choose from these models or contact us for a customized baler to meet your unique requirements.

| Baler Model | Bale Size (L x W x H) | Bale Weight | Feed Opening (L x W) | Press Force (max.) | Bales Per Hour (approx.) |

| HBB40A | 700mm x 400mm x 300mm (28” x 16” x 12”) |

20-25kg (44-55lbs) Wood shavings |

1200mm x 700mm (47” x 28”) |

40tons (88,000lbs) |

45 |

| HBB40B | 790mm x 390mm x 220mm (31” x 15” x 8.7”) |

16-20kg (35-44lbs) Wood shavings |

1500mm x 790mm (59” x 31”) |

40tons (88,000lbs) |

120 |

| HBB60 | 700mm x 400mm x 300mm (28” x 16” x 12”) |

25-30kg (55-66lbs) Wood shavings |

1200mm x 700mm (47” x 28”) |

60tons (132,000lbs) |

45 |

| HBB80 | 700mm x 400mm x 300mm (28” x 16” x 12”) |

35-40kg (77-88lbs) Sawdust |

1200mm x 700mm (47” x 28”) |

80tons (176,000lbs) |

45 |

*Specifications & Dimensions are subject to change without prior notice. Bale weights and performance rates are approximate and depending on material type, feed speed, and other variables in baling process.

Heavy-duty Bagging Baler Frequently Asked Questions

Bagging baler is also named compression bagger. As its name indicates, the machine can not only compress the material, but also bag the compressed material into a bag. The compressed and bagged cubic bales are stackable and easy for storage and transport.

- Higher compressing force makes denser bales.

- Higher efficiency.

- Bigger bale size and bale weight.

- Compatible to various feeding methods such as belt conveyor, screw conveyor.

- Wide material applications such as wood shavings, shredded paper, shredded cardboard, sawdust, rice husk, leaves, etc.

All loose material in small pieces, which are not suitable to be tied up by straps or wires. Such as wood shavings/chips, sawdust, rice husk, shredded paper, shredded cardboard, hops, peanut shells, stevia leaves, cottonseeds, chopped straw/hay, haylage, hops, hemp flowers, etc.

The baler works very simple. Feed the material, and set a plastic or woven bag over the bale exit chute, then you just operate the buttons on the control panel, the machine will compress and eject the bale automatically.

GOT A QUESTION ABOUT THE HAYLAGE BALER?

Talk with One of Our Experts in Waste Recycling Solutions

Our skilled professional team is waiting to help you with your unneeded waste materials and propose to you our recycling solutions. We also back up these proposals with our able technical support to make your recycling efforts earn more money by being more efficient.