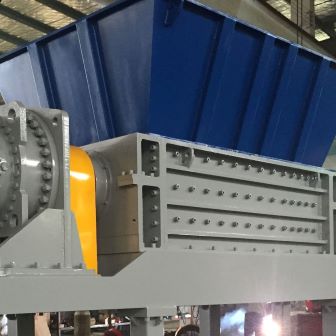

DXL SERIES TWO SHAFT SHREDDER

Large-Duty Two Shaft Shredder: The Colossus of Waste Size Reduction Solutions!Our DXL series Double Shaft Shredders are large-duty shredding machines, which are engineered with PLC control system, capable of automatic forward, reverse and stopping, ensuring fully automated operation of the equipment, making the machine operation safer and more reliable. The two-shaft shredder is renowned for its low-speed, high-torque, and minimal noise features. It is tailored to handle a multitude of waste types that are extremely big and thick difficult-to-break, across diverse industries. Outfitted with dual shafts, high resistant blades, and high-torque shearing shafts, this series of shredders cater to large-scale operations with ease, offering unmatched throughput rates. In industrial settings, this dual-shaft shredder often serves as the initial shredding machine, particularly in scenarios where variations in the final size of the shredded material are permissible. |  |

|

|

Features & Benefits Of The DL Series Two Shaft Shredder:

|

Main Feature Details

HIGH-TORQUE SHEARING CAPABILITY

Allowing them to shred tougher and more resilient materials with ease.

DURABLE BLADES

Made of top-grade steel, ensuring longevity and consistent performance.

LARGE HOPPER

Can increase capacity, accommodate larger materials, improve workflow, and reduce labor cost.

AUTOMATED CONTROL SYSTEM

Advanced PLC controls for automated operation, real-time diagnostics, and safety features like auto-reverse and overload protection.

The DXL Series Two Shaft Shredder Machine Can Shred:

Plastics

Paper & Cardboard

Wood & Biomass

E-waste & Electronics

Textile & Fabrics

Rubber

Urban Waste

Soft Metals

The Right Powerful Industrial Double Shaft Shredder For The Job!

Makabale offers 3 models of DXL Series Dual-shaft Shredder for sale. These shredders are built for a variety of waste material types and industries. Choose from the models or contact us for an industrial waste shredder to meet your unique shredding requirements.

| Model | Motor Power | Rotor Diameter | Rotor Speed | Cutting Chamber | Throughput (approx.) |

| DXL6180 | 55kW x 2 (75hp x 2) | 800mm (31") | 7.5rpm | 1808mm x 1510mm (71" x 59") | 2500kg/h (5500lbs/h) |

| DXL6180A | 55kW x 2 (75hp x 2) | 756mm (30") | 5.4+3.6rpm | 1808mm x 1510mm (71" x 59") | 3000kg/h (6600lbs/h) |

| DXL6250 | 75kW x 2 (100hp x 2) | 800mm (31") | 7.5rpm | 2508mm x 1510mm (99" x 59") | 4000kg/h (8800lbs/h) |

GOT A QUESTION ABOUT THE DXL SERIES TWO SHAFT SHREDDER?

Talk with One of Our Experts in Waste Recycling Solutions

Our skilled professional team is waiting to help you with your unneeded waste materials and propose to you our recycling solutions. We also back up these proposals with our able technical support to make your recycling efforts earn more money by being more efficient.