DRUM CRUSHER / DRUM COMPACTOR

Efficient Drum Crusher - Save Disposal Cost, Reduce 90% Storage SpaceAlso known as a drum compactor or barrel compactor, this machine can simplify your operations by compressing barrels or drums in a single stroke. The machine can compress drums up to 220 liter (58 gallon). There is no tying or wrapping involved, ultimately saving you time and money. The operator simply places the drum in the chamber, closes the door, and presses a button on the control panel. The ram automatically moves down and compresses the drum. With the compressing force, the machine easily achieves a compression ratio of 12-to-1, compressing the drum to a stackable, easily stored size of approximately 10 cm in height. This greatly reduces the needed storage space and transportation costs because the compressed drums take up much less space. Puncture spikes on the platen ensure safe pressure release and metal blockers ensure the drum does not shift during compression. A drainage channel ensures that any residual liquids in the drum are safely drained away. Ideal For: Recycling Centers, Distribution Centers, Manufacturing Plants, Recyclers, Scrapyards, Garages, Other Industrial/Commercial Applications. |  |

|

|

Features And Benefits Of The Drum Crusher / Compactor:

|

Main Feature Details

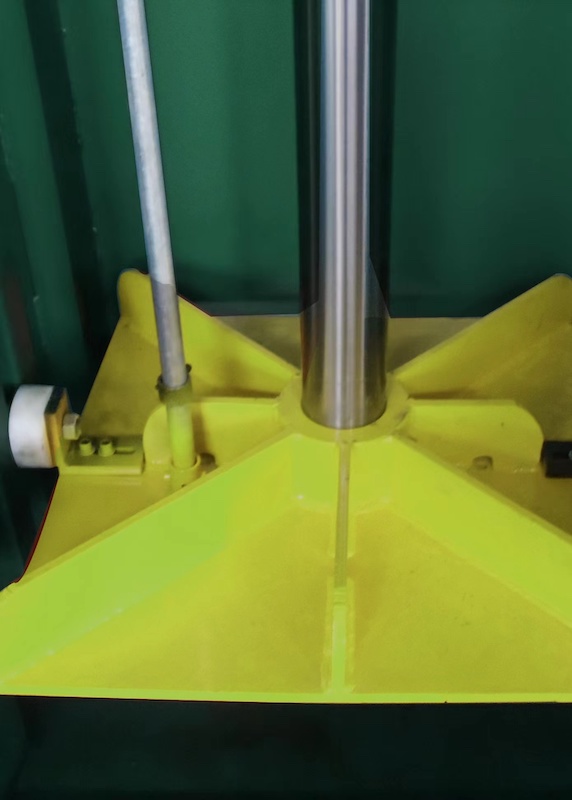

DRUM RING LOCATOR

Drum ring locator is used to keep the drum aligned in the chamber.

LIQUID DRAINAGE CHANNEL

Liquid drainage channel is to drain the liquid out of the baler if there is any residue in the drums. It helps you keep a safe and clean baling area.

SPIKES UNDERNEATH THE PLATEN

Piercing spikes underneath the press platen puncture the drum and release the air pressure in pressing process for safe and efficient operation.

SAFETY INTERLOCK SYSTEM

An interlock system is fixed in the chamber door to ensure safe operation. The platen will not move if the door is open.

The Drum Crusher / Compactor Can Crush:

Steel Drum/Barrel

The Right Drum Crusher / Compactor For The Job!

Makabale offers 2 standard models of hydraulic drum crusher / compactor for sale. Both the drum presses are built for commercial and industrial applications of all types of waste drum disposal. Choose from these models or contact us for a customized drum crusher to meet your unique requirements.

| Baler Model | Compressing Chamber Size (L x W x H) | Flattened Drum Height | Feed Opening (L x H) | Press Force (max.) | Bales Per Hour (approx.) |

| VDC30 | 760mm x 760mm x 1000mm (30” x 30” x 39”) |

100-130mm (4-5”) | 760mm x 1000mm (30” x 39”) | 30tons (66,000lbs) | 70 |

| VDC40 | 760mm x 760mm x 1000mm (30” x 30” x 39”) |

80-100mm (3-4”) | 760mm x 1000mm (30” x 39”) | 40tons (88,000lbs) | 70 |

*Specifications & Dimensions are subject to change without prior notice. Bale weights and performance rates are approximate and depending on material type, feed speed, and other variables in baling process.

Drum Crusher / Drum Compactor Frequently Asked Questions

Drum crusher is a recycling machine used to flatten used empty drums or barrels into low height drums just like “pancakes”.

All businesses who generate waste empty drums, drum recyclers, scrapyards, recycling centers.

58 gallon steel drums, 55 gallon steel drums, and any smaller waste drums.

Drum crusher works very simple. Firstly, put in empty drum into the compressing chamber; then close the door and press the button on the electric control panel; the machine will crush the drum automatically; lastly, open the door and take out the flattened drum.

Both of our 30ton pressing force model and 40ton pressing force model are perfect for crushing a 55-gallon drum.

The Makabale hydraulic drum crusher has a small footprint of 1100mm x 950mm (84” x 37”).

VDC30 drum crusher weighs about 960kg (2,112lbs).

VDC40 drum crusher weighs about 1000kg (2,000lbs).

GOT A QUESTION ABOUT THE DRUM CRUSHER?

Talk with One of Our Experts in Waste Recycling Solutions

Our skilled professional team is waiting to help you with your unneeded waste materials and propose to you our recycling solutions. We also back up these proposals with our able technical support to make your recycling efforts earn more money by being more efficient.