PET BALER / ALUMINUM CAN BALER

The PET Baler / Aluminum Can Baler Is A Baler Machine With Combination Of Baling And Liquid Extraction.This baler is specifically designed to bale PET bottles, HDPE containers, aluminum cans, tin cans, and other hollow waste material. It does a fantastic job of making sure every piece of material in the chamber is fully pressed by incorporating an exceptionally long stroke. The operator manually loads the material into the chamber, closes the door, and presses a button on the control panel to start baling. After a bale is done, the machine will safely eject the compressed bale for further handling. The innovative design includes a liquid drainage tray that ensures proper drainage of any residual liquids, which keeps your recycling area clean and safe. The design also includes retaining teeth, which prevents the compressed materials from springing back and increases the stability and density of the bales. This is a must-have solution for plastic bottle and aluminum can recycling facilities. Ideal For: Bottling Plants, Breweries, Supermarkets, Retail Stores, Hotels, Schools, Grocery Stores, Hospitals, Offices, Restaurants, Recycling Centers, Manufacturing Facilities, Other Industrial and Commercial Sites. |  |

|

|

Features And Benefits Of The PET Baler / Aluminum Can Baler:

|

Details And Options

STANDARD AUTO CHAIN BALE EJECTOR

After a bale is tied up, place the ejector hooks onto the platen lugs in the back of the baler. The bale will be automatically ejected out from the bale chamber with the platen retracts.

BALE HEIGHT ADJUSTABLE

Bale height limitator enables you to adjust the bale height that you want to make.

OPTIONAL HYDRAULIC CHAMBER DOOR

The baler chamber door can automatically open or close by pressing a button on electric panel instead of handwheel, which saves labor and increases efficiency.

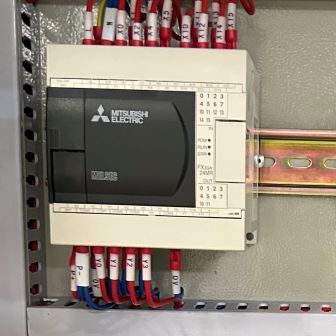

OPTIONAL PLC CONTROL

PLC control makes baler operation more precise and stable. Direct and easy for fault diagnosis and troubleshooting.

LONG CYLINDER STROKE

Extra-long cylinder stroke ensures full compaction of every hollow product inside the baling chamber.

LIQUID DRAINAGE CHANNEL

Liquid drainage channel is to capture and drain the liquid residuals out of the baler if the bottles or cans contain liquid. This helps you keep a safer and cleaner baling area.

SAFETY INTERLOCK SYSTEM

An interlock system is fixed in the feeding door to ensure safe operation. The platen will not compress if doors are open.

OPTIONAL FEEDING CONVEYOR

Automatic feeding conveyor is optional for saving labor and maximizing output.

The Makabale PET Baler / Aluminum Can Baler Is Typically To Bale:

PET Bottles

PET bottle is one of the most used packaging materials for beverage, water and juice owing to its nature of highly recyclable and other advantages. While the hollow characteristics and residual liquids in the bottles can be headaches on transportation and baling during recycling process. This long-lasting Makabale PET bottle baling machine is exactly what you need for baling PET bottles. Take model VPB30 as an example, about up to 5,000 PET bottles can be compressed and baled into a 31" x 24" x 28" (800 mm x 600 mm x 700 mm) bale with weight approximately 220 lbs (100 kg). It helps you save space, save labor, and save cost.

Aluminum Cans

Aluminum can is the most sustainable beverage packaging as it is completely recyclable and mostly recycled in a closed loop, which means used aluminum beverage cans can be reproduced into new aluminum cans after a series of recycling processes. One vital step in aluminum can recycling industry is using aluminum can balers to compress and bale large amounts of individual cans into dense rectangular cubes which are convenient and cost-efficient to handle, store and ship. Makabale aluminum can balers are a wise investment, as combined with the longer life of the machine, Makabale aluminum can balers will produce more baled material, faster, over a longer period of time.

The Right PET Baler / Aluminum Can Baler For The Job!

Makabale offers 4 standard models of vertical plastic bottle baler / aluminum can baler for sale. All these liquid exaction baler models are built for a variety of products and industries. Choose from these models or contact us for a customized baler to meet your unique requirements.

| Baler Model | Bale Size (L x W x H) | Bale Weight (PET bottle) | Feed Opening (L x H) | Press Force (max.) | Bales Per Hour (approx.) |

| VPB30 | 800mm x 600mm x up to 700mm (31” x 24” x up to 28”) |

45-100kg (99-220lbs) | 800mm x 400m (31” x 16”) |

30tons (66,000lbs) | 3 |

| VPB40 | 1000mm x 600mm x up to 900mm (39” x 24” x up to 35”) |

60-150kg (132-330lbs) | 1000mm x 450mm (39” x 18”) |

40tons (88,000lbs) | 2 |

| VPB50 | 1100mm x 700mm x up to 1000mm (43” x 28” x up to 39”) |

70-250kg (154-550lbs) | 1100mm x 500mm (43” x 20”) |

50tons (110,000lbs) | 2 |

| VPB80 | 1100mm x 700mm x up to 1000mm (43” x 28” x up to 39”) |

150-400kg (330-880lbs) | 1100mm x 500mm (43” x 20”) |

80tons (176,000lbs) | 2 |

*Specifications & Dimensions are subject to change without prior notice. Bale weights and performance rates are approximate and depending on material type, feed speed, and other variables in baling process.

PET Baler / Aluminum Can Baler Frequently Asked Questions

To make a perfect plastic bottle bale,

Firstly, place a piece of cardboard on the bottom of the baling chamber.

Secondly, feed your bottles into the baler through the feed opening until the chamber is full and compressing.

Thirdly, repeat feeding and compressing, and place another piece of cardboard on the top of the material at the last cycle.

Lastly, tie off the bale and eject out the bale.

Firstly, you need to check your volume of scrap bottles, and you also need to check your nearest recycler who will pick up your bales and how much they will pay you. Then it will be a wise idea to choose a best suited bottle baler for your business and help your business more profitable.

Baler is a recycling machine used to compact the large volume of waste material into small and neat cubes, for easy and cost savings on handling, storage, and transportation. Baler machine can help recycling businesses more efficiently and profitably. Bottle baler and can baler are just some of the various type of balers.

A PET bale is a bundle of crushed PET bottles, usually in cubic shape and with high density. It is for saving storage and transportation cost and easy handling. Turning large volumes of empty PET bottles into dense bales is a key step in PET recycling process. And a suitable PET bottle baler is a must-have piece of machine during this recycling process.

1. Connect the electrical power supply and switch power “ON” in the electric box.

2. Switch to “SEMIAUTO” mode and press “START” button to start the motor.

3. Open the feeding gate and feed material until the chamber is full.

4. Close the feeding gate. Press “PRESS” button. The platen will automatically press and retract.

5. Repeat feeding and pressing cycles until the bale height reaches set value, the platen will automatically stop in the down position and hold the bale. Another way, you can also switch to “PACK” mode to stop the platen in the down position at that cycle.

6. Open the chamber door by rotating the decompression wheel.

7. Insert baling wires through the slots in the chamber bottom and platen.

8. Tie off the bale.

9. Go to the back of the machine and hook up the ejecting chain on the platen.

10. Press “BACK” button. The platen will move upward and the bale will be ejected out. Please keep clear in front of the baler.

11. Take the ejecting chain down from the platen and move the bale to where you stack it.

No, it is no need to spend labor to open the bottle caps before baling. Even if there is some liquid residue inside the bottles, this plastic bottle baler machine can drain away the liquid, leaving you a clean working environment.

GOT A QUESTION ABOUT THE PET BALER / ALUMINUM CAN BALER?

Talk with One of Our Experts in Waste Recycling Solutions

Our skilled professional team is waiting to help you with your unneeded waste materials and propose to you our recycling solutions. We also back up these proposals with our able technical support to make your recycling efforts earn more money by being more efficient.