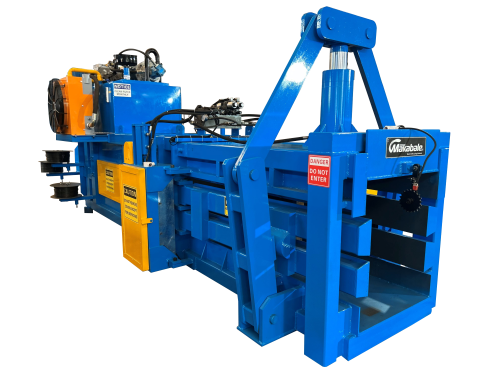

AUTO-TIE / AUTOMATIC HORIZONTAL BALER

The Auto-Tie Horizontal Baler Is A High Production And Fully Automatic Recycling Baler.This open ended automatic horizontal baler is designed to efficiently to bale a wide range of materials, such as old corrugated cardboard (OCC), carton boxes, paper, shredded paper, textiles, industrial offcuts, plant fibers, RDF, and more. What's convenient about this baler for you is that the whole process is fully automatic and is continuous without your need to watch over it. The only thing that your staff has to oversee is when the material is loaded into the conveyor. Then afterwards, when using the forklift to transfer the completed bales to the location that they are to be stacked. Built with heavy-duty construction, advanced hydraulic system, and reliable computerized control system, it offers user-friendly operation and long-lasting performance. The intelligent color touch screen provides you with many useful functions such as bale length setting, diagnostics and more. This auto tie baler line covers 6 models with press forces ranging from 40 to 200 tons, accommodating various capacity needs, from smaller operations to large volume load. Tailor-made solutions are also available to fit specific requirements. Ideal For: Cardboard/Paper Recyclers, Distribution Centers, Manufacturing Plants, Printing Plants, Warehouses, Recycling Centers, Scrap Yards, Plant Fiber Dealers, MRFs, RDFs. |  |

|

|

Features And Benefits Of The Auto Tie Baler:

|

Details And Options

COLOR TOUCH SCREEN

Intuitive color touch screen provides lots of functions such as bale count, bale length setting, diagnostics, etc.

BALE EXIT GUIDE

This feature gives you the convenience of removing in a faster manner the completed bales.

OPTIONAL INFEED STEEL CONVEYOR

If you want continuous and automatic feeding, you can make use of the conveyor option. There are 2 types of conveyors: underground (pit) type and the above ground type.

SHEAR BLADES

This feature is available for ensuring continuous feeding and the prevention of a jam to happen.

The Makabale Horizontal Auto-Tie Baler Can Bale:

Cardboard/OCC

Paper

Paper Carton

Plant Fiber

Soft Plastics

Municipal Waste

RDF

Shredded Paper

Un-chopped Straw/Hay

The Right Fully Automatic Horizontal Baler For The Job!

Makabale offers 6 standard models of open-end auto-tie baler for sale. All these baler models are built for a variety of products and industries. Choose from these models or contact us for a customized baler to meet your unique requirements.

| Baler Model | Bale Size WxH (Cross Section) | Bale Weight (OCC) | Feed Opening (L x W) | Press Force (max.) | Throughput (approx.) |

| HAT40 | 720mm x 800mm (28" x 31") |

200-250kg (440-550lbs) Based on bale length 1200mm |

1000mm x 720mm (39” x 28”) |

40 tons (88,000lbs) |

1.4-2.5 ton/h |

| HAT60 | 720mm x 800mm (28" x 31") |

250-300kg (550-660lbs) Based on bale length 1200mm |

1200mm x 720mm (47” x 28”) |

60 tons (132,000lbs) |

1.6-3 ton/h |

| HAT80 | 1100mm x 800mm (43" x 31") |

300-400kg (660-880lbs) Based on bale length 1400mm |

1300mm x 1100mm (51” x 43”) |

80 tons (176,000lbs) | 2.1-4 ton/h |

| HAT100 | 1100mm x 800mm (43" x 31") |

600-700kg (1320-1540lbs) Based on bale length 1500mm |

1500mm x 1100mm (59" x 43") |

100 tons (220,000lbs) |

4-7 ton/h |

| HAT150 | 1100mm x 1100mm (43" x 43") |

800-1100kg (1760-2420lbs) Based on bale length 1600mm |

2000mm x 1100mm (79" x 43") |

150 tons (330,000lbs) |

6-11 ton/h |

| HAT200 | 1100mm x 1100mm (43" x 43") |

900-1200kg (1980-2640lbs) Based on bale length 1600mm |

2000mm x 1100mm (79” x 43”) |

200 tons (440,000lbs) |

8-12 ton/h |

*Specifications are for reference only and are subject to change without prior notice. Bale weights and throughputs are approximate and depending on material type, feed speed, and other variables in baling process.

Horizontal Auto-tie Baler Frequently Asked Questions

Horizontal auto-tie balers have a hopper above the baling chamber to collect the material and the main cylinder works in horizontal orientation. Waste materials are fed into the hopper until it is full, then the main ram compresses the material. When a bale is made, the machine will automatically tie the bale and eject it out.

Horizontal automatic baler is commonly used for processing large volume of waste materials with high productivity. It is a fully automatic machine and with a wide range of material applications. Therefore, it is the best baling solution for businesses who are seeking for achieving the maximum of efficiency with the minimum of manpower.

Save labor – Fully automatic operation means the minimum labor required. The conveyor feed the material, and the baler machine transforms the loose material into dense bales which are continuously ejected out from the baler end. These cubic bales are stacked neatly and ready for transportation.

High productivity – with fast 14-16 second cycle time, horizontal auto-tie balers produce more bales than manual-tie balers and generate high production.

Consistent bales – the bales produced by horizontal auto-tie balers are more consistent which is much more convenient and optimized for container loading and handling.

Wide material applications – a horizontal auto-tie baler can process various waste types including cardboard, OCC, paper, plastics, non-ferrous, textile.

Compatible to various feeding devices – many feeding options can be connected to the baler machine, either conveyor, or grapple, dumper, cyclone.

Increase profitability – the reduced labor cost, transportation cost, and operation cost; the more materials you can ship at each time; the more space you have for materials storage. All these aspects contribute to your increasingly revenue.

The auto-tie baler works very easy. First, feed material into the hopper by conveyor or other device; then the main ram starts compressing cycles; when a bale is complete, the machine ties off the bale and eject it out of the baler automatically. Lastly, move the finished bales to where they are stacked.

The horizontal automatic baler can process many material types, such as cardboard, OCC, carton, paper, other paper-based products, plastic bottles, films, soft plastic packaging, aluminum cans, and plant fiber (i.e. Coir fiber).

Auto-tie horizontal baler can help your operation reduce large volumes of waste and make your recycling business more profitable and efficient. Auto-tie baler is easy to operate, but as a machine, using them correctly is vital to reduce the downtime and keep safety. Here are some tips for the auto-tie horizontal baler.

1. Make sure the doors of electric box and operation box are closed. This will avoid electric short circuit caused by moisture or dust.

2. All pressure of hydraulic power unit is adjusted to optimal condition. Any adjustment should be under the permission of machine supervisor.

3. If you cannot start the motor, it is highly possibly caused by thermal relay overload of the magnetic switch of motor. Check and find out the reason that causes overload, then reset the “Reset” bar.

4. Always keep the auto-tie baler clean and maintain the machine periodically according to maintenance guidance. Check and tighten all bolts and screws (especially at electric connection) to avoid abnormality.

5. Always check the wires to make sure each wire is going through in order.

6. If the ram moves forward and backward without stop, it may be due to some material residue stuck in front of the photo sensor inside the hopper. Simply remove the material residue to resolve the matter.

7. If the machine encounters difficulties to complete the baling cycle, stop the motor and let the threaders move back to its home position. If threaders are not back to home position for more than one hour, it is likely damaged.

8. Feed materials continuously and in uniform speed to maximize the throughput.

9. Hydraulic oil should be changed 6 months after commencing operations. After that, change it once a year.

10. Make sure temperature of hydraulic oil is within 0 to 60 degrees Celsius when the machine is in operation.

11. Make sure the hydraulic station is in a ventilated area.

GOT A QUESTION ABOUT THE AUTO-TIE BALER?

Talk with One of Our Experts in Waste Recycling Solutions

Our skilled professional team is waiting to help you with your unneeded waste materials and propose to you our recycling solutions. We also back up these proposals with our able technical support to make your recycling efforts earn more money by being more efficient.